23 Physical Acceleration Models

In this workshop, we’ll learn how to use physical acceleration models to convert results from reliability tests done under laboratory conditions (which may be slightly unrealistic) into estimates that match real outcomes in the field!

Figure 23.1: Crash Testing with LEGOs: a very safe prototype

Getting Started

Load Packages

Let’s start by loading the tidyverse and broom packages! Also, sometimes select gets overruled by other packages, so it can help to load it directly.

23.1 Acceleration Factor

23.1.1 Stress vs. Usage Conditions

Imagine: You work in Dearborn, Michigan, testing airbag failure rates with car crash dummies every day. Your work helps people stay safe on the road! Unfortunately, lab conditions tend to be a little more extreme than the real world. Moisture levels, temperature, speed, friction, etc. are very hard (nay impossible) to perfectly match to real driving conditions. A product life distribution measured under lab “stress” conditions will always be slightly off from the real, “use”-case life distribution by a specific factor. What if we could measure and approximate that factor?

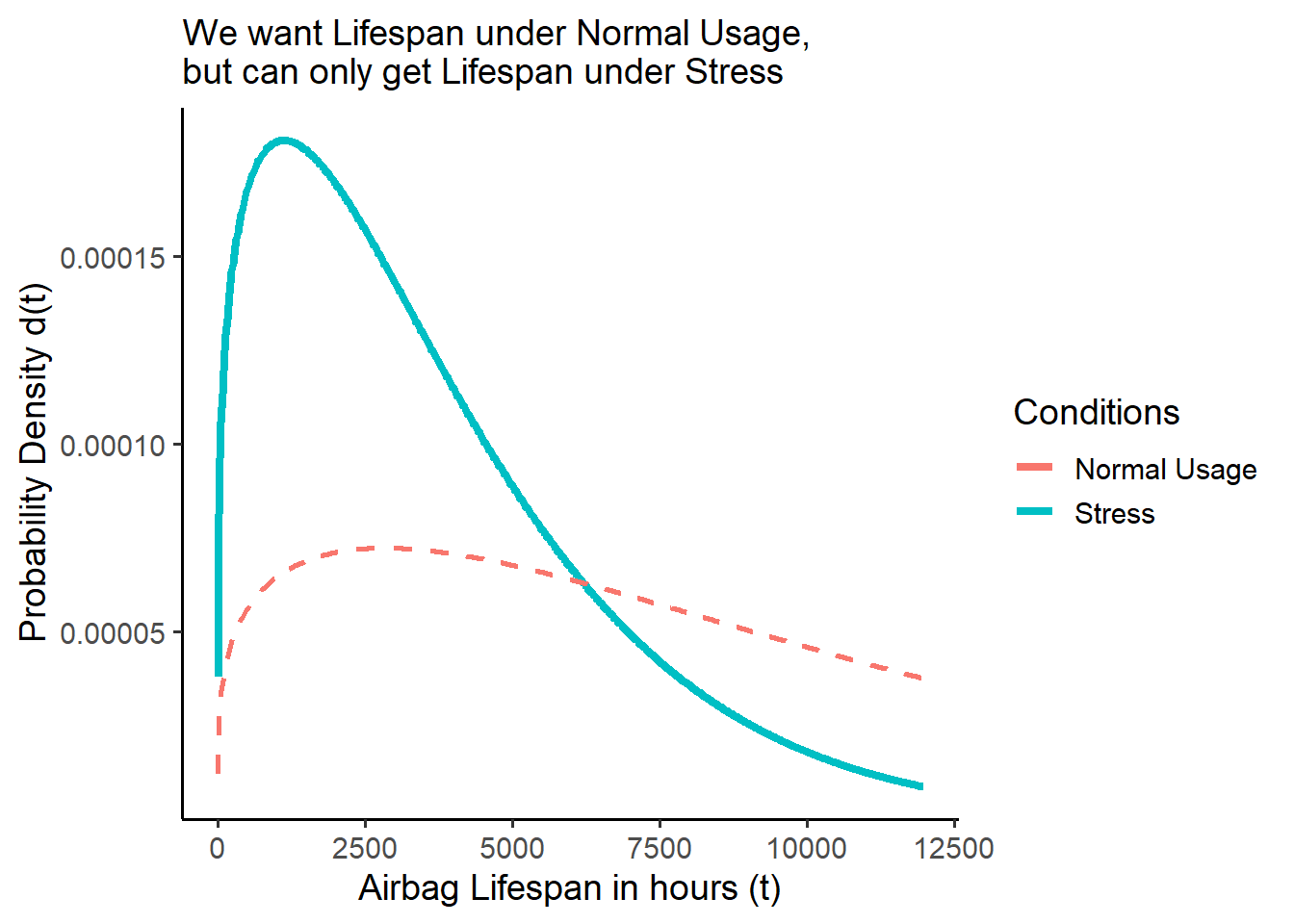

Suppose researchers are stress testing airbags in the lab! Their empirical data reveals the airbag lifespans are Weibull distributed, with a characteristic life of c = 4100 hours and a shape parameter of m = 1.25. They write the Weibull density function (PDF) d() below, and use it to calculate and visualize the probability the airbags fail every hour from 1 to 8000 hours.

They can visualize the blue density curve of the stress-tested airbags shown below (\(s\)), called \(f_s(t)\).

But what they really want to know is the red dashed curve of the airbags under normal use conditions (\(u\)), called \(f_u(t)\)! But they don’t know it!

Fortunately, they know that in past on-road and off-road studies, the median airbag’s time to failure was

250%times greater under normal usage as when under stress condition. We write250%here the Acceleration Factor \(AF\) (or \(A\)), because it describes how stress-testing accelerates the failure by a factor of2.5. We can write it like:

\[f_u(t) = f_s(t) \times AF = f_s(t) \times 2.5 \]

# Let's write ourselves a speedy weibull density function 'd()'

d = function(t, m, c){

(m / t) * (t / c)^m * exp(-1*(t/c)^m)

# or dweibull(t, scale = c, shape = m)

}

airbags <- data.frame(t = seq(1, 12000, by = 20)) %>%

mutate(d_stress = d(t, c = 4100, m = 1.25)) %>%

# Suppose the lifespans under normal usage are just off by a factor of ~2.5

# then we could project the PDF under normal usage like:

mutate(d_usage = d(t = t / 2.5, c = 4100, m = 1.25) / 2.5)

ggplot() +

# Plot the PDF under stress conditions

geom_line(data = airbags, mapping = aes(x = t, y = d_stress, color = "Stress"),

size = 1.5) +

# Plot the PDF under normal usage conditions

geom_line(data = airbags, mapping = aes(x = t, y = d_usage, color = "Normal Usage"),

size = 1, linetype = "dashed") +

# Add a nice theme and clear labels

theme_classic(base_size = 14) +

labs(x = "Airbag Lifespan in hours (t)", y = "Probability Density d(t)",

color = "Conditions",

subtitle = "We want Lifespan under Normal Usage,\nbut can only get Lifespan under Stress")

23.1.2 Acceleration as a Function \(\frac{f_{s}(t)}{f_{u}(t)}\)

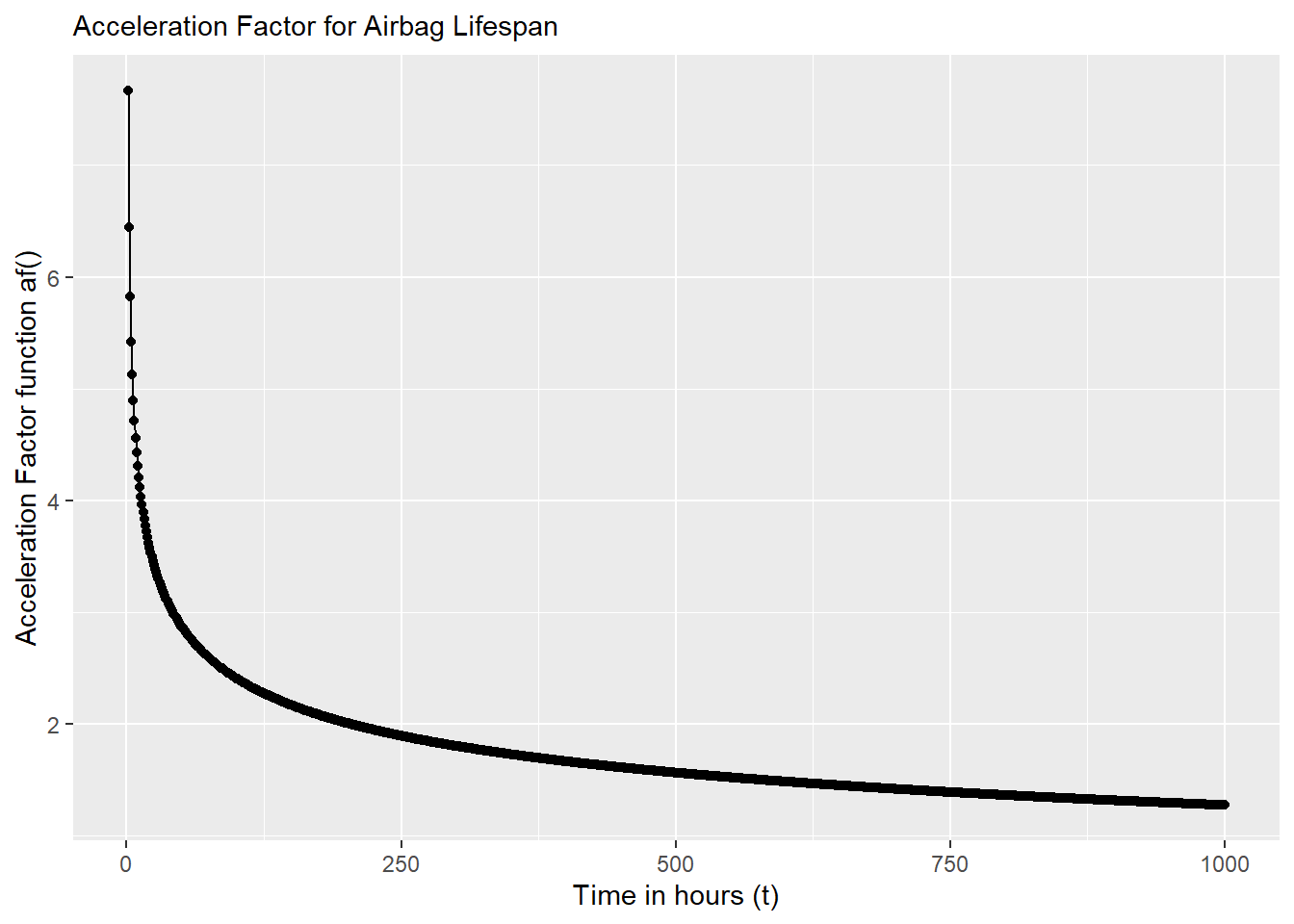

In reality, \(f_{u}(t)\) probably doesn’t have exactly a constant relationship with \(f_{s}(t)\). In a perfect world, we could collect raw data for both lifetimes under normal conditions \(t_u\) and under stress-testing \(t_s\), and then estimate their density functions \(f_u(t)\) and \(f_s(t)\). We could then calculate \(AF\) exactly as a function af() that relates them. For example:

# Let's write an acceleration factor function!

af = function(t){

# Find density under stress

ds <- d(t, m = 1.25, c = 4100)

# Find density function under normal conditions

du <- d(t, m = 1.5, c = 4500)

# Since f_u(t) = f_s(t) x AF,

# then AF = f_s(t) / f_u(t) = ds / du

ds / du

}Were we to plot it, we can see below AF is not constant here, but varies over time, because \(f_u(t)\) and \(f_s(t)\) vary over time. So, when we pick an AF, we’re usually picking the AF corresponding to a specific parameter, like the characteristic life or median of a distribution.

data.frame(

time = 1:1000,

af = af(1:1000)

) %>%

# Visualize it!

ggplot(mapping = aes(x = time, y = af)) +

geom_line() + geom_point() +

labs(subtitle = "Acceleration Factor for Airbag Lifespan",

y = "Acceleration Factor function af()",

x = "Time in hours (t)")

Supposing that \(t_{u} = t_{s} \times AF\), we can say several more things:

\[ Failure \ Function = F_{u}(t) = F_{s}(t/AF) \] \[ Density \ Function = f_{u}(t) = \frac{f_{s}(t/AF)}{AF} \] \[ Failure \ Rate = z_{u}(t) = \frac{z_{s}(t/AF)}{AF} \]

23.1.3 Linear Acceleration

However, it’s usually very difficult to obtain the density functions for both usage and stress conditions. That’s why we want acceleration factors (AF) - because they’ll let use estimate \(f_u(t)\) when we only have \(f_s(t)\). So in practice, we usually assume \(AF\) shows a constant, linear relationship between \(f_{u}(t)\) and \(f_{s}(t)\), like when \(AF = 2.5\). This is called linear acceleration.

Linear acceleration requires us to choose a constant value of \(AF\) from just 1 time-step from the plot above. How can we choose!? We should probably choose a fairly representative lifespan, based off a parameter like the median time to fail \(T_{50}\) (or the mean time to fail \(m\), characteristic life \(c\), etc.). Even if we don’t have access to all the raw data, if we know the median lifespan under stress \(T_{50_{s}}\) and under normal conditions \(T_{50_{u}}\), we can estimate \(AF\) by taking \(AF = \frac{T_{50_{u}}}{T_{50_{s}}}\). For example:

# Let's write a weibull quantile function

q = function(p, c, m){ qweibull(p, scale = c, shape = m) }

# Get median under stress

median_s <- q(0.5, c = 4100, m = 1.25)

# Get median under normal conditions

median_u <- q(0.5, c = 4500, m = 1.5)

# Calculate it!

af = median_u / median_s

# Check the Acceleration Factor!

af## [1] 1.152529Let’s clear this data.

Learning Check 1

Question

A kitchen mixer has an exponential distributed lifespan. Labs stress tested the mixer at 125 degrees Celsius, yielding a mean time to fail of 4500 hours. But, it is usually heats to 32 degrees Celsius, and has an acceleration factor of 35.

What proportion of mixers do we expect will fail by 40,000 hours under normal use?

[View Answer!]

# Given an acceleration factor of 35

af <- 35

# Write a failure function

f = function(t, lambda){ 1 - exp(-t*lambda) }

# Method 1:

# Failure Function = fu(t) = fs(t/AF)

f(t = 40000 / af, lambda = 1 / 4500)## [1] 0.2242836# Method 2:

# We know that lambda = zu(t) = zs(t/AF) / AF

# so... plus that in for lambda

f(t = 40000, lambda = 1 / (4500 * af) )## [1] 0.2242836We expect ~22% of mixers will fail after 40,000 hours when running at 32 degrees Celsius.

Learning Check 2

Question

Suppose we want no more than 10% of components to fail after 40,000 hours at normal usage conditions. So, we redesign the mixer to operate at a lower temperature. What (linear) acceleration factor is needed to project from our 125 degree conditions in lab to the normal use temperature of 32 degrees?

[View Answer!]

# Write failure function

f = function(t, lambda){ 1 - exp(-t*lambda) }

# Failure Function = fu(t) = fs(t/AF)

# 0.10 = fu(t = 40000) = 1 - exp(-40000*lambda)

# log(1 - 0.10) = -40000*lambda

lambda_u = -log(0.90) / 40000

lambda_s = 1/4500

# Get ratio between these parameters

# lambda_u = 1 / af * lambda_s

# so...

af = lambda_s / lambda_u

# Check acceleration factor!

af## [1] 84.36641We would need an acceleration factor af of ~84.4.

23.2 Modeling Normal Use Lifespan

23.2.1 Models and Prediction

A model is an equation approximating the relationship between two or more vectors of data. It’s not the real thing - it’s an approximation! Why use models? Usually we know quite a lot about the conditions under which a product was tested in lab, but we can’t actually observe the characteristic lifespan of that product under normal use conditions. But if we can make a really good model of the relationship between the outcome and those conditions, then we can predict for any set of conditions what the outcome - the characteristic lifespan of a product - would be under those conditions.

Fortunately, R was built to make statistical models! To make a model of lifespans, we need 4 ingredients.

an outcome

vector, saved in adata.frame.1 (or more) vectors of condition/predictors, saved in the same

data.frame.the

lm()function inR, which makes a linear model drawing the line of best fit between each value of the predictor(s) and outcome. The model is the equation of that line!the outcome

vectorneeds to be log-transformed, because (a) most useful life distributions involve exponential processes and (b) lifespans are by nature non-negative, right-skewed variables. Takinglog(outcome)adjusts for that and lets us plot a straight line of best fit.

- Note: We’ll learn more in later weeks about how*

lm()makes models, but for now, we’ll assume it’s magic!*

For example, let’s think about a car alternator, the device that converts mechanical energy into electrical energy in a car. We’ll make a few tiny example models!

Suppose we tested 5 samples of 100 alternators each, and recorded the results in our alt data.frame below. We calculated the characteristic life in each of our 5 samples in the c, but our samples were all subjected to different stress conditions: different temperatures in Celsius (temp), which were converted into units of temperature factor scores (tf); different voltage levels in volts; at different points in the devices’ lifespan (time, in hours); and with different average performance ratings (rating) in amps.

alt <- tibble(

# Characteristic life in hours

c = c(1400, 1450, 1500, 1550, 1650),

# Temperature in Celsius

temp = c(160, 155, 152, 147, 144),

# Temperature Factor (a standardized unit)

tf = 1 / (1 / 11605 * (temp + 273.15)),

# Voltage, in volts

volts = c(17, 16.5, 14.5, 14, 13),

# Hours of life spent by time of test

time = c(1200, 1000, 950, 600, 500),

# Performance Rating, in Amps

rating = c(60, 70, 80, 90, 100))Let’s use this data to explore some of the different classic physical acceleration models, including the Arrhenius Model, Eyring Model, and Degradation Model.

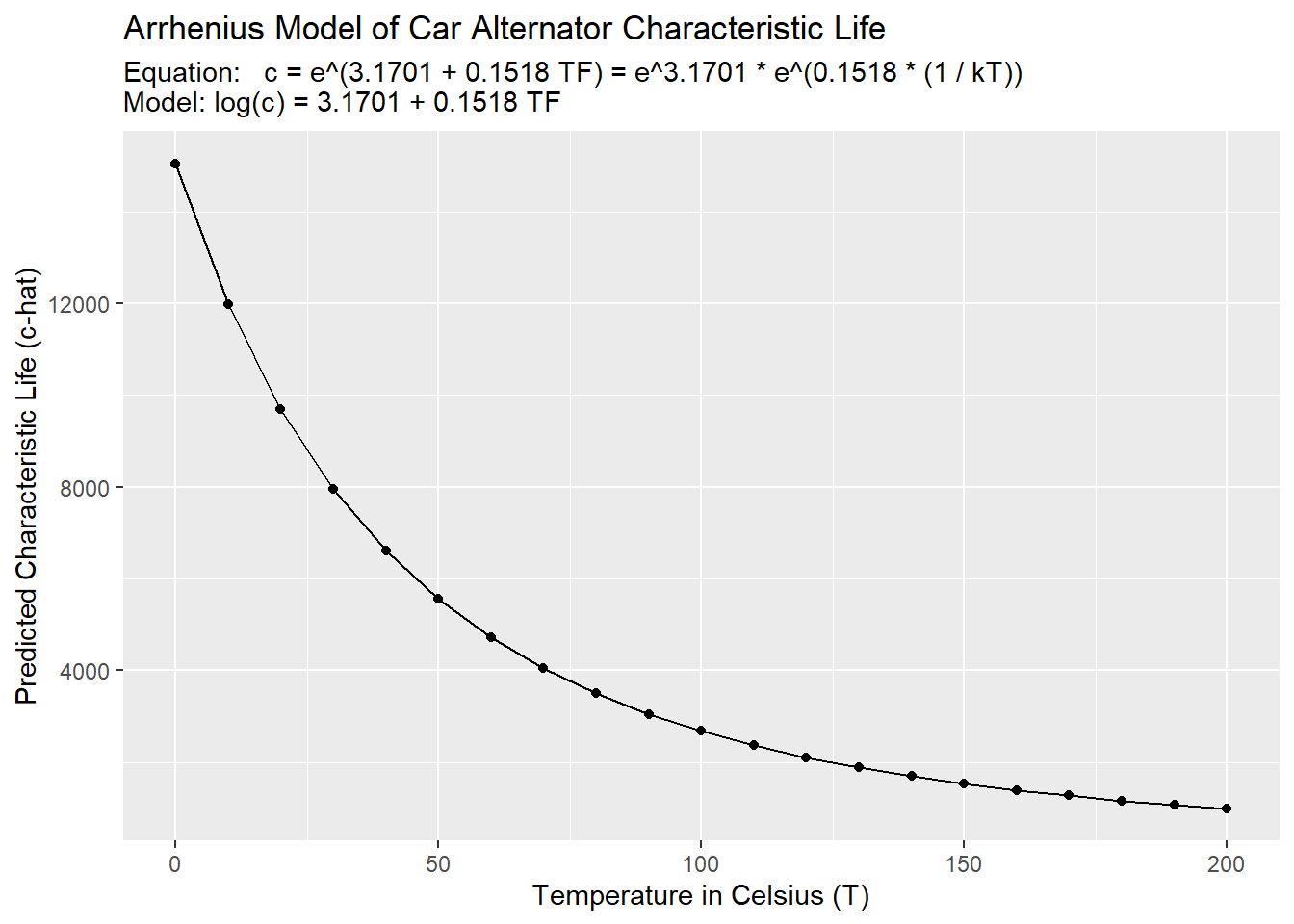

23.2.2 Arrhenius Model (Temperature)

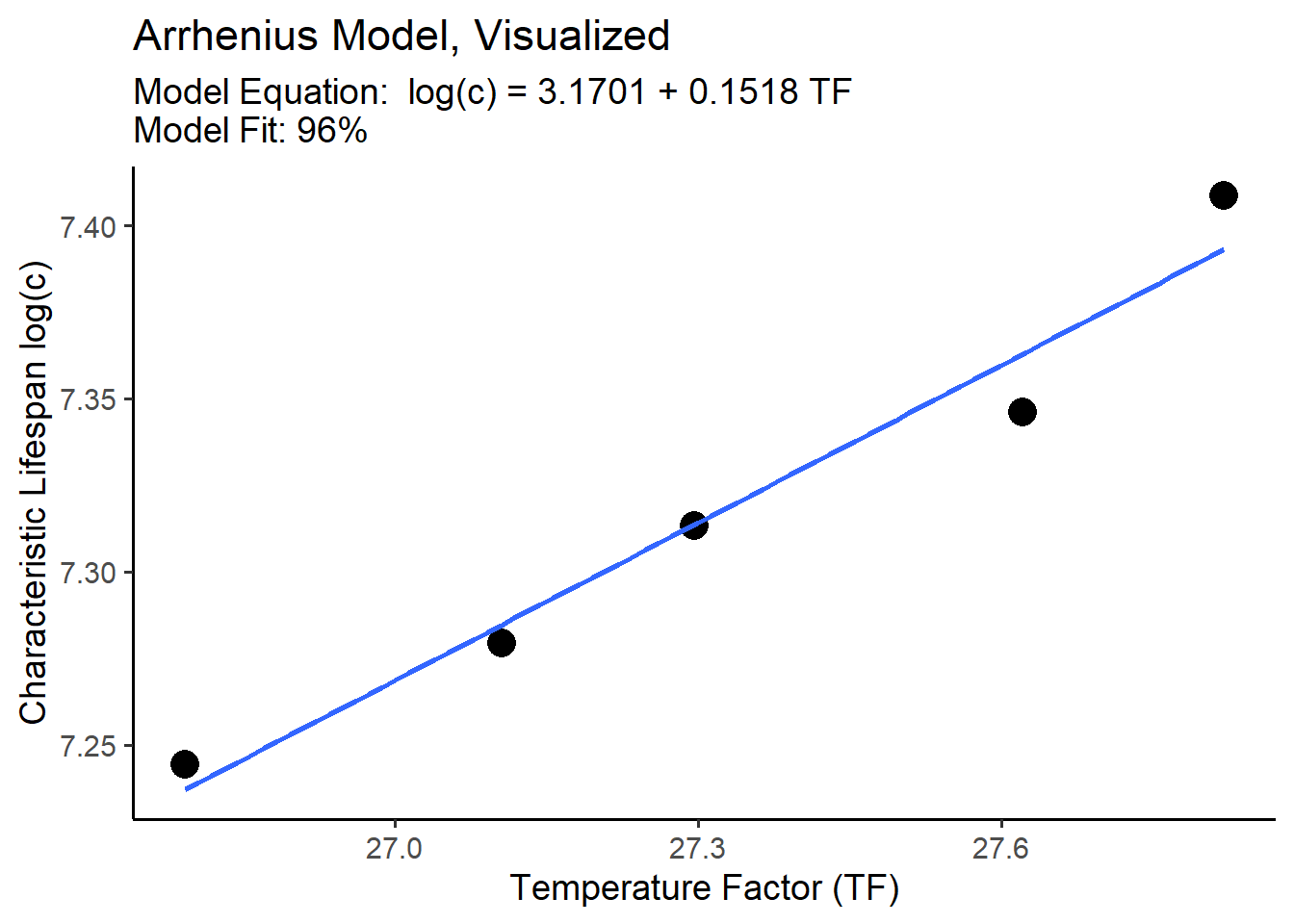

The Arrhenius Model is a simple equation that models the impact of temperature (tf) on the log() of lifespan (c). Let’s explore it visually using ggplot(), and then estimate it using lm().

23.2.3 Visualizing the Arrhenius Model

We could visualize the relationship between each of these conditions and the log() of the characteristic lifespan c using…

geom_point()which makes a scatterplot betweenxandycoordinates in theaes().geom_smooth(method = "lm"), which finds the line of best fit.

g <- alt %>%

ggplot(mapping = aes(x = tf, y = log(c) )) +

geom_point(size = 5) + # Add scatterplot points

geom_smooth(method = "lm", se = FALSE) # Make line of best fit, using lm() - a linear model

# we can write 'se = FALSE' (standard error = FALSE) to get rid of the confidence intervalWe can also add in the equation of this line of best fit (which we’ll calculate below), plus other labels.

g +

# Add theme

theme_classic(base_size = 14) +

# Add labels

labs(title = "Arrhenius Model, Visualized",

subtitle = "Model Equation: log(c) = 3.1701 + 0.1518 TF \nModel Fit: 96%",

# We can add a line-break in the subtitle by writing \n

x = "Temperature Factor (TF)", y = "Characteristic Lifespan log(c)")

23.2.4 Estimating the Arrhenius Model

So how did R calculate that line of best fit? It used the lm() function to make a linear model - an equation, which fits the data with a specific accuracy rate (eg. 96%). Let’s make a model m1 to predict the log() of characteristic lifespan c, based on our temperature factor vector tf in alt!

First, let’s make the model with lm(), piping our vectors from alt.

Second, let’s inspect the model’s fit with glance() from the broom package, and select() the r.squared statistic. 0% means terrible model fit. 100% means the model equation perfectly predicts every value of log(c) in our alt data.frame. We aim for excellent predictive power where possible. 96% is excellent!

## # A tibble: 1 × 1

## r.squared

## <dbl>

## 1 0.962Third, we can now read the model equation for our line of best fit.

##

## Call:

## lm(formula = log(c) ~ tf, data = .)

##

## Coefficients:

## (Intercept) tf

## 3.1701 0.1518The lm() function estimated our model equation m1, including 2 constant coefficients named (Intercept) and tf. These coefficients show the y-intercept ((Intercept)), called \(\alpha\) and the slope/effect/rate of change called \(\beta\) for every 1 unit increase in the temperature factor tf. We can write this model equation formally as:

\[ \begin{align*} log(c) =& \ Intercept + Slope \ \times TF \\ or:& \\ log(c) =& \ \alpha + \beta \times TF, \\ & where \ \alpha = 3.1701 \ and \ \beta = 0.1518, \\ so:& \\ log(c) =& \ 3.1701 + 0.1518 \ TF \\ so:& \\ c =& e^{\alpha + \beta \times TF} \\ or:& \\ c =& \ e^\alpha \times e^{\beta \times TF} \\ or:& \\ c =& e^{3.1701} + e^{0.1518 \ TF} \\ or:&\\ Arrhenius \ Model:& \\ c =& A + e^{\Delta H \times TF} \ \\ &\ where \ A = e^{Intercept} = e^{\beta} \ \ and \ \Delta H = Slope = \beta \\ also:& \\c =& A + e^{\Delta H \times (1 / (k T))} \\ &where \ TF = 1 / (k \times T_{Kelvin}) \ and \ k = 1 / 11605 \end{align*} \] As you can see above, there are many ways to write the Arrhenius model, but it boils down to this: any linear model of the log-characteristic life will involve:

a y-intercept constant called \(\alpha\) (\(log(A)\) in the Arrhenius model). \(\alpha\) describes how much

log(c)we get independent of any other factors (ie: iftf = 0).- Interpreting our model: If the temperature factor \(TF = 0\), our model predicts that \(log(c) = 3.1701\).

a slope constant called \(\beta\) describing the effect of your variable (\(TF\) or

tf), for every 1 unit increase in your variable. In the Arrhenius model, \(\beta\) is written as \(\Delta H\), the ‘activation energy’ rate at which a temperature factor increase of 1 unit affectslog(c).- Interpreting our model: If the temperature factor \(TF\) increases by 1, our model predicts that \(log(c)\) will change by \(\beta = \Delta H = 0.1518\).

And that’s how we read any statistical model with two variables!

<br

23.2.5 Prediction

Now that we have our model equation (and, importantly, a good fitting one), we can feed it values of our predictor \(TF\) (generically called \(X\)) to calculate our predicted log of the characteristic life \(log(\hat{c})\) (generically called \(log(\hat{Y})\)). We can do this two ways: (1) by writing a function or (2) using the predict() function in R.

Writing our own function works the same way as writing our d(), f(), or r() function. We’ll call it c_hat().

# For any value of tf, we can now calculate c_hat.

# We write the model equation for log(c), then exponentiate it with exp()!

c_hat = function(tf){ exp( 3.1701 + 0.1518*tf) }

# Test it!

c_hat(tf = 28)## [1] 1669.868It works! The characteristic life for tf = 28 is ~1670.

# Or better yet, let's calculate temperature factor 'tf' too,

# so we only have to supply a temperature in Celsius

tf = function(temp){

k = 1 / 11605 # Get Boltzmann's constant

1 / (k * (temp + 273.15)) # Get TF!

}

# Now predict c_hat for 30, 60, and 90 degrees celsius!

c_hat = function(temp){ exp( 3.1701 + 0.1518*tf(temp)) }

c(30, 60, 90) %>% c_hat()## [1] 7952.275 4712.271 3044.511So cool!

Wouldn’t it be nice though, if we could simplify that process? The predict() function in R can help! The predict function will run your model equation on any newdata that you feed it, calculating the predicted outcomes. newdata must be formatted as a data.frame, containing vectors named to match each predictor from your original data (which we named alt).

Let’s make a data.frame of fakedata with tibble(), varying temperature from 0 to 200 degrees Celsius, and then transform that into a temperature factor tf with our tf() function.

fakedata <- tibble(

temp = seq(0, 200, by = 10),

tf = tf(temp))

# Check the first 3 rows!

fakedata %>% head(3)## # A tibble: 3 × 2

## temp tf

## <dbl> <dbl>

## 1 0 42.5

## 2 10 41.0

## 3 20 39.6Then, we’ll feet our 21 rows of fakedata and our model m1 to the predict() function, which will output 21 predictions for log(c).

## 1 2 3 4 5 6 7 8

## 9.619376 9.391606 9.179376 8.981148 8.795580 8.621497 8.457864 8.303769

## 9 10 11 12 13 14 15 16

## 8.158401 8.021038 7.891038 7.767824 7.650877 7.539733 7.433969 7.333203

## 17 18 19 20 21

## 7.237091 7.145316 7.057591 6.973655 6.893267But we can exponentiate it with exp() to get c_hat!

## 1 2 3 4 5 6 7

## 15053.6495 11987.3387 9695.1035 7951.7546 6604.9840 5549.6862 4711.9837

## 8 9 10 11 12 13 14

## 4039.0668 3492.5958 3044.3360 2673.2172 2363.3224 2102.4897 1881.3274

## 15 16 17 18 19 20 21

## 1692.5112 1530.2759 1390.0440 1268.1516 1161.6437 1068.1196 985.6159We could even write the whole thing inside a tibble() function:

fakedata <- tibble(

temp = seq(0, 200, by = 10),

tf = tf(temp),

# Predict c_hat

c_hat = predict(m1, newdata = tibble(tf)) %>% exp())

# View the first 3 rows!

fakedata %>% head(3)## # A tibble: 3 × 3

## temp tf c_hat

## <dbl> <dbl> <dbl>

## 1 0 42.5 15054.

## 2 10 41.0 11987.

## 3 20 39.6 9695.And now, we can plot the line of best fit between temp and c_hat, which are the quantities we actually care about.

g2 <- fakedata %>%

ggplot(mapping = aes(x = temp, y = c_hat)) +

geom_line() +

geom_point()

# add some labels!

g2 +

labs(x = "Temperature in Celsius (T)", y = "Predicted Characteristic Life (c-hat)",

title = "Arrhenius Model of Car Alternator Characteristic Life",

# Here's a little trick for cleanly adding linebreaks in subtitles:

# Just write a paste() function

subtitle = paste(

"Equation: c = e^(3.1701 + 0.1518 TF) = e^3.1701 * e^(0.1518 * (1 / kT))",

"Model: log(c) = 3.1701 + 0.1518 TF", sep = "\n"))

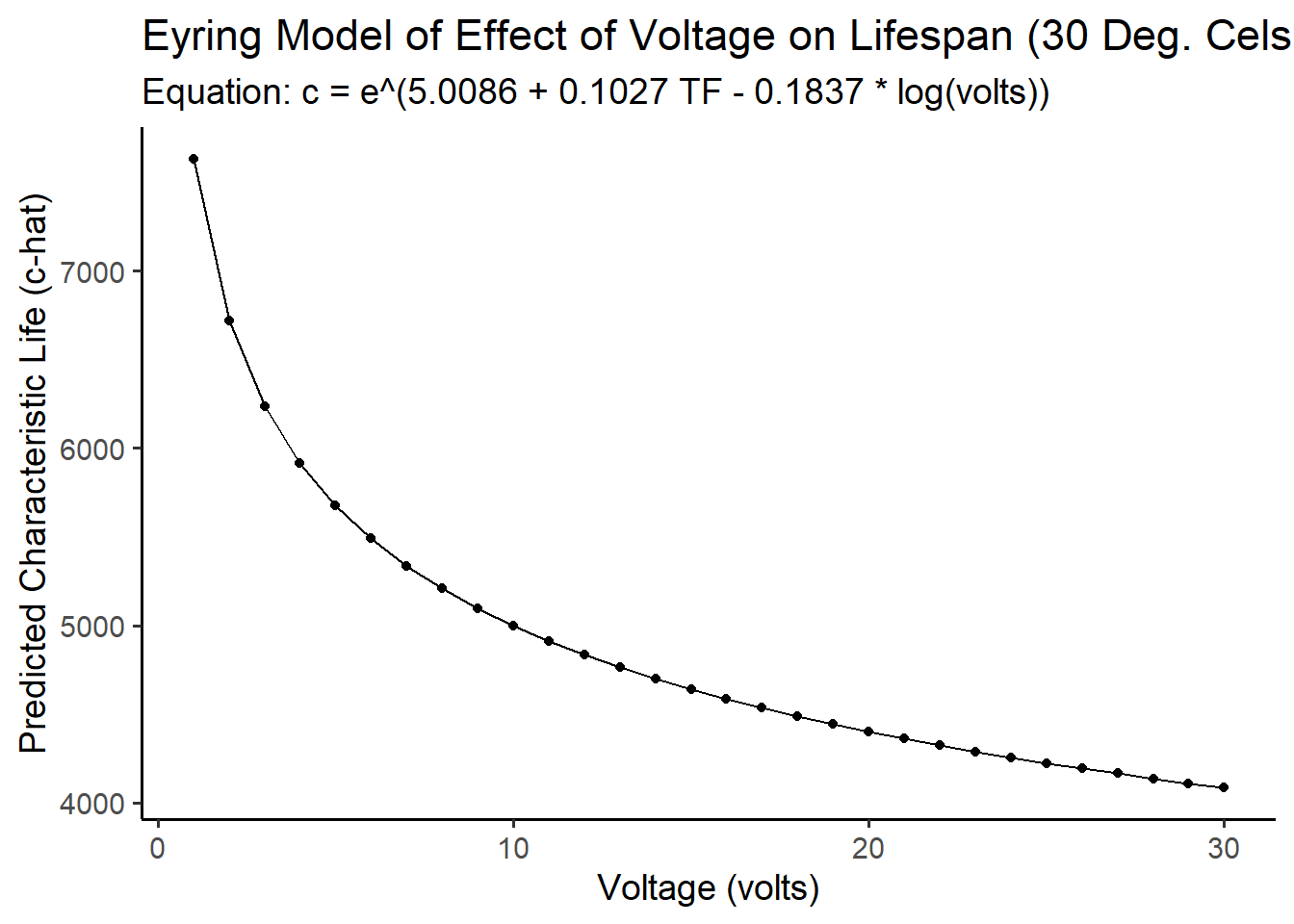

23.3 Eyring Model (Multiple Stressors)

But in our alt data, multiple conditions varied, including tf but also volts and time. These might each have independent effects on log(c)! So let’s estimate their effect by adding some more coefficients to our model!

The Eyring Model provides an equation derived from chemical reaction theory and quantum mechanics, which supposes that we can predict lifespan parameters pretty well if we know temperature and any other stresses, such as voltage. The general form of the Eyring Model can also be distilled into a multivariate regression equation. This means instead of drawing a line of best fit approximating the relationship between 2 vectors (log(c) and tf), we can approximate the relationship between 3 vectors (log(c), tf, and volts), making a plane.

\[ \begin{align*} c =& AT^{\alpha} \times e^{\frac{\Delta H}{kT}} \times e^{(B + C/T) \times S} \\ &where: \ T = Temperature \ in \ Kelvin, \\ &so: \ if \ \alpha = 0, \ T^{\alpha} = 1 \\ &also:\\ &where: \ S = Stressor \ S, \\ &and: \ B + C/T = \ temperature \ contigent \ effect \ of \ S\\ \\ &simplifies \ to: \\ c=&e^{intercept} \times T^{\alpha} + e^{\Delta H \times (1 / (kT)) \ + \ (B + C/T)^S } \\ \\ & so \ assuming \ \ T^{\alpha} = 1: \\ log(c) =& intercept \ + \ \Delta H \times (1 / (kT)) + (B + C/T)\times S \\ & can \ be \ rewritten \ as: \\ log(c) =& \alpha \ + \ \beta_1 X_1 + B_2 X_2 + ... \\ & where \ \alpha = intercept, \\ &X_1 = Temperature \ Factor = TF = 1 / (kT), \\ &\beta_1 = effect \ of X_1 \ [Temperature \ Factor], \\ &X_2 = Stressor \ S, \\ &B_2 = net \ effect \ of \ X_2 \ [Stressor \ S] \\ &... = any \ other \ stressors \end{align*}\]

This is a monster of an equation, but we can still model it relatively simply using a linear model lm() of the log(c).

Often, we care about voltage, which can be written as:

\[ \beta_{2}X_{2} = B \times (-log(V)), \ where \ \beta_2 = B = effect \ of \ -log(Voltage) \]

We can write model this as m2, like so:

##

## Call:

## lm(formula = log(c) ~ tf + log(volts), data = .)

##

## Coefficients:

## (Intercept) tf log(volts)

## 5.0086 0.1027 -0.1837Then, we can just supply predict() with any values of tf and volts to predict log(c_hat), and exponeniate the result.

fakedata <- tibble(

# Hold temperature constant

temp = 30,

tf = tf(temp),

# But vary volts

volts = seq(from = 1, to = 30, by = 1),

# Predict c_hat

c_hat = predict(m2, newdata = tibble(tf, volts)) %>% exp())And we can visualize our fakedata to see the impact of changing volts on c_hat as temp and tf were held constant.

fakedata %>%

ggplot(mapping = aes(x = volts, y = c_hat)) +

geom_line() +

geom_point() +

theme_classic(base_size = 14) +

labs(title = "Eyring Model of Effect of Voltage on Lifespan (30 Deg. Celsius)",

subtitle = "Equation: c = e^(5.0086 + 0.1027 TF - 0.1837 * log(volts))",

x = "Voltage (volts)", y = "Predicted Characteristic Life (c-hat)")

23.4 Degradation Model (Time Trends)

One final common impact on lifespan is simple degradation in functioning over time. With each passing day, the product is exposed to a stressor an additional time, bringing it a little closer to whatever we define as failure, and in turn, impacting the estimation of performance across our samples.

We can model this as…

\[ \begin{align*} Q_t =& \ Q_0 \times e^{-R(S)t} \\ &where: \\& Q_t = performance \ metric \ at \ time \ t, \\& Q_0 = starting \ value \ at \ t = 0, \ and \\& R(S) = effect \ of \ stressor \ S \ \\ \\& modeled \ as: \\ log(Y_t) =& \ \alpha + \beta X \times t \\ &where: \\&log(Y_t) = log(Q_t), \\ & \alpha = intercept = log(Q_0), \\& \beta = -R = degradation \ effect \ of \ S,\\& X = stressor \ S \ (sometimes \ excluded), \ and \\ &t = time \ t \\&or: \\ log(Y_t) =& \ \alpha + \beta \times t \\& where: \beta = overall \ degradation \ effect \ of \ time \ t \end{align*} \]

Let’s try this out using our alt data!

We might expect the power rating of an alternator might decline over time. We could model the overall degradation effect on the log(rating) by regressing a single vector time against our model. This produces a great fit of ~94%.

## # A tibble: 1 × 1

## r.squared

## <dbl>

## 1 0.940Alternatively, if the degradation effect depends on another condition, like how much voltage was run on it, we could write an interaction effect using I(volts * time). This forces our model to be written as \(log(Y) = \alpha + \beta X \times t\) instead of just \(log(Y) = \alpha + \beta \times t\).

##

## Call:

## lm(formula = log(rating) ~ I(volts * time), data = .)

##

## Coefficients:

## (Intercept) I(volts * time)

## 4.825e+00 -3.497e-05We could even apply these effects right into our estimation of characteristic life \(\hat{c}\) for our alternators! Perhaps we think the characteristic life would tend to be lower if the sample were measured later in time, after being exposed to higher volts. Let’s estimate this model as m3!

m3 <- alt %>%

lm(formula = log(c) ~ tf + log(volts) + I(volts * time))

# Really good fit!

m3 %>% glance()## # A tibble: 1 × 12

## r.squared adj.r.squared sigma statistic p.value df logLik AIC BIC

## <dbl> <dbl> <dbl> <dbl> <dbl> <dbl> <dbl> <dbl> <dbl>

## 1 0.981 0.924 0.0174 17.3 0.174 3 17.2 -24.4 -26.3

## # ℹ 3 more variables: deviance <dbl>, df.residual <int>, nobs <int>As you can see, we can build nearly as complex models as you can imagine! A good rule of thumb is to seek to build the most parsimonious (simplest) model that explains the most variation (maximizes the r.squared)

Figure 23.2: Wasn’t that fun?

23.5 Burn-in Periods

Sometimes, manufacturers will deliberately test-run their products for several hundred hours before selling them, just to ‘burn-in’ to their lifespan distributions. The idea is, if they can force the defective products to fail early on, then the products that remain are less likely to fail. Acceleration Factors can help us identify the ideal burn in period.

We can say:

\(z(t)\) = failure rate curve with no burn-in.

\(z_b(t)\) = failure rate curve after a burn-in period of \(t_b\) hours.

\(a\) = acceleration factor between normal use vs. stress (burn-in), so:

\(z_b(t = 0) = z(a \times t_b)\): failure rate after 0 hours of burn-in \(z_b(t = 0)\) should equal the normal failure rate at a time \(a\) times greater than the burn-in period of \(t_b\) hours.

In other words, we can use the acceleration factor \(a\) to project the conditional probability of failure after surviving burn-in. We can say, hey, what’s the probability of failure under normal use \(t\) hours after burn-in \(F_b(t)\), given that we know it survived up through the burn-in period \(t_b\) and its use-to-stress relationship is characterized by an acceleration factor of \(a\)?

# Let's write the Weibull density and failure function, as always...

d = function(t, c, m){ (m / t) * (t / c)^m * exp(-1*(t/c)^m) }

f = function(t, c, m){ 1 - exp(-1*((t/c)^m)) }Since we can calculate \(F(t)\) as f(t,c,m) and \(f(t)\) as d(t,c,m), we can write the conditional probability of failure post-burn-in as:

\[ F_b(t) = \frac{ F(t + a t_b) - F(at_b)}{ 1 - F(at_b) } \] And we can code it as:

fb = function(t, tb, a, c, m){

# Change in probability of failure

delta_failure <- f(t = t + a*tb, c, m) - f(t = a*tb, c, m)

# Reliability after burn-in period

reliability <- 1 - f(t = a*tb, c, m)

# conditional probability of failure

delta_failure / reliability

}Let’s try it!

# 1000 hours after burn-in

# with a burn-in period of 100 hours

# an acceleration factor of 20

# characteristic life c = 2000 hours

# and

# shape parameter m = 1.5

fb(t = 1000, tb = 100, a = 20, c = 2000, m = 1.5)## [1] 0.5670432Likewise, the conditional density function \(f_b(t)\) can be written as:

\[ f_b(t) = \frac{ f(t + at_b)}{ 1 - F(at_b)} \]

# And we'll write the condition

db = function(t, tb, a, c, m){

density <- d(t = t + a*tb, c, m)

reliability <- 1 - f(t = a*tb, c, m)

# get conditional density

density / reliability

}Let’s try it! What’s the conditional probability of having a lifespan of 1000 hours, given that you had a burn-in period of 100 hours? Let’s assume an acceleration factor of 20, characteristic life of 2000 hours, and a shape parameter of 1.5, like before.

## [1] 0.0003976962

23.6 Maximum Likelihood Estimation (MLE) for Physical Acceleration Models

But how in the world did we get all these estimates of c in the first place? Often, we end up calculating it via maximum likelihood estimation (MLE) from cross-tabulated readout data.

Suppose we have several cross-tabulations of readout data available to us about the occurrence of failure for wheels by temperature. We know these are Weibull distributed, but we don’t know the distributions’ parameters for each temperature level, let alone the \(\Delta H\) or the Acceleration Factor \(AF\)!

The examples below will focus on samples of car wheels, each with a Weibull distribution, but they are equally applicable to other distributions.

# Let's write Weibull density, failure, and reliability functions

d = function(t, c, m){ (m / t) * (t / c)^m * exp(-1*(t/c)^m) }

f = function(t, c, m){ 1 - exp(-1*((t/c)^m)) }

r = function(t, c, m){ 1 - f(t,c,m) }

23.6.1 MLE for an Example Arrhenius Model

# Let's load in our crosstable

wheels <- tibble(

label = c("[0,1000]", "(1000,2000]", "(2000,3000]", "(3000,4000]", "(4000,5000]"),

t = c(500, 1500, 2500, 3500, 4500),

temp_100 = c(106, 66, 22, 4, 2), # out of 200 wheels

temp_150 = c(125, 25, 25, 15, 10), # out of 175 wheels

temp_200 = c(140, 30, 15, 10, 15)) # out of 300 wheels

# Check it!

wheels## # A tibble: 5 × 5

## label t temp_100 temp_150 temp_200

## <chr> <dbl> <dbl> <dbl> <dbl>

## 1 [0,1000] 500 106 125 140

## 2 (1000,2000] 1500 66 25 30

## 3 (2000,3000] 2500 22 25 15

## 4 (3000,4000] 3500 4 15 10

## 5 (4000,5000] 4500 2 10 15We can write a maximum likelihood estimation function to find the most likely parameters for our products stress tested at 100 degrees Celsius, using optim() to perform MLE.

# Let's write our crosstable's likelihood function

ll = function(t, x, par){

r = sum(x) # Get total failures

n = 200 # Record total sampel size

tmax = max(t) # Record last time step

# Get the product of the log-densities at each time step, for all failures then

prob_d = ((d(t, c = par[1], m = par[2]) %>% log()) * x) %>% sum()

# For the last time step, get the probability of each remaining unit surviving

prob_r = r(t = tmax, c = par[1], m = par[2])^(n - r) %>% log()

# Get joint log-likelihood

prob_d + prob_r

}

# And let's run MLE!

mle100 <- optim(par = c(1000, 1), t = wheels$t, x = wheels$temp_100, fn = ll,

control = list(fnscale = -1))

# Our characteristic life and shape parameter m!

mle100$par## [1] 1287.316800 1.511327But doesn’t it seem like a waste that we have all this data at multiple temperature readouts, but we’re just relying on one temperature to estimate parameters? We can do better! Let’s write a maximum likelihood estimator that maximizes more parameters!

We’ll assume that the shape parameter \(m\) is the same for each distribution, but the characteristic life varies (a common assumption in physical acceleration models).

# Let's write our crosstable's likelihood function

ll = function(t, x1, x2, x3, par){

# Get total failures

r1 = sum(x1)

r2 = sum(x2)

r3 = sum(x3)

# Record total sample size in each

n1 = 200

n2 = 175

n3 = 300

tmax = max(t) # Record last time step

# Get the product of the log-densities at each time step, for all failures then

prob_d1 = ((d(t, c = par[1], m = par[4]) %>% log()) * x1) %>% sum()

prob_d2 = ((d(t, c = par[2], m = par[4]) %>% log()) * x2) %>% sum()

prob_d3 = ((d(t, c = par[3], m = par[4]) %>% log()) * x3) %>% sum()

# For the last time step, get the probability of each remaining unit surviving

prob_r1 = r(t = tmax, c = par[1], m = par[4])^(n1 - r1) %>% log()

prob_r2 = r(t = tmax, c = par[2], m = par[4])^(n2 - r2) %>% log()

prob_r3 = r(t = tmax, c = par[3], m = par[4])^(n3 - r3) %>% log()

# Get joint log-likelihood, across ALL vectors

prob_d1 + prob_r1 + prob_d2 + prob_r2 + prob_d3 + prob_r3

}

# And let's run MLE!

mle <- optim(par = c(1000, 1000, 1000, 1), t = wheels$t,

x1 = wheels$temp_100,

x2 = wheels$temp_150,

x3 = wheels$temp_200,

fn = ll, control = list(fnscale = -1))

# Check out our 3 characteristic life parameters,

# for temp_100, temp_150, and temp_200, and our shared shape parameter!

mle$par## [1] 794.06372 1491.73881 1747.74451 1.02723We can apply MLE to estimate as many parameters as our computers and patience for coding functions will allow!

23.6.2 Estimating \(\Delta H\) with MLE

Next, let’s use our MLE values to estimate \(\Delta H\), the impact of temperature on lifespan parameters.

# Remember our function to calculate temperature factors

tf = function(temp){ 1 / ((1 / 11605) * (temp + 273.15)) }

# Let's collect our parameter estimates

param <- tibble(

# For each temperature

temp = c(100, 150, 200),

# report the MLE c estimates

c = mle$par[1:3],

# and the shared MLE m estimate

m = mle$par[4],

# and Calculate TF (for each temperature...)

# This will be our independent variable

tf = tf(temp))

# Check it!

param## # A tibble: 3 × 4

## temp c m tf

## <dbl> <dbl> <dbl> <dbl>

## 1 100 794. 1.03 31.1

## 2 150 1492. 1.03 27.4

## 3 200 1748. 1.03 24.5Now, we’ve got three different \(c\) estimates. We’d really like to project, for any temperature temp, what would the characteristic life c be? Fortunately, we know we can estimate that with a line of best fit.

## # A tibble: 1 × 12

## r.squared adj.r.squared sigma statistic p.value df logLik AIC BIC

## <dbl> <dbl> <dbl> <dbl> <dbl> <dbl> <dbl> <dbl> <dbl>

## 1 0.932 0.863 0.154 13.6 0.168 1 3.00 0.00617 -2.70

## # ℹ 3 more variables: deviance <dbl>, df.residual <int>, nobs <int>Now that we’ve built a fairly good model, we can use it to predict the characteristic life \(c\) for any temperature temp.

And if we have c_hat(), then all of a sudden, we can calculate the probability of failure at any time t! Suppose our wheel was used at 30 degrees Celsius. Our model projects a probability of failure of 32% by the 100th hour! (Don’t buy that wheel!)

tibble(

t = 100,

temp = 10,

tf = tf(temp),

# Predict c-hat for our specified temperature

c_hat = predict(m4, newdata = tibble(tf)) %>% exp(),

# Grab our MLE estimate of m

m = mle$par[4],

# And calculate the probability of failure, given a use temperature of 30

prob_f = f(t, c = c_hat, m = m)

)

23.6.3 Visualizing Probabilities

We can even then make some rad graphs!

For example, we can vary time but hold constant temperature to calculate the probability of failure over time at a specific temperature.

tibble(

t = seq(0, 2000, by = 10),

tf = tf(temp = 30),

# Get parameters

c_hat = predict(m4, newdata = tibble(tf)) %>% exp(),

m = mle$par[4],

# Calculate Probability

prob_f = f(t, c = c_hat, m = m)

) %>%

ggplot(mapping = aes(x = t, y = prob_f)) +

geom_area() +

labs(x = "Time", y = "Failure Function F(t)",

subtitle = "Probability of Failure at 30 Degrees Celsius")Or, we can hold constant time but vary temperature, to show the changing probability of failure given different stress levels by temperature.

tibble(

t = 1000,

temp = seq(0, 200, by = 10),

tf = tf(temp),

# Get parameters

c_hat = predict(m4, newdata = tibble(tf)) %>% exp(),

m = mle$par[4],

# Calculate Probability

prob_f = f(t, c = c_hat, m = m)

) %>%

ggplot(mapping = aes(x = temp, y = prob_f)) +

geom_area() +

labs(x = "Temperature (Celsius)", y = "Failure Function F(t)",

subtitle = "Probability of Failure after 1000 hours")