16 Statistical Process Control in Python

Figure 2.1: Statistical Process Control!

In this workshop, we will learn how to perform statistical process control in Python, using statistical tools and plotnine visualizations! Statistical Process Control refers to using statistics to (1) measure variation in product quality over time and (2) identify benchmarks to know when intervention is needed. Let’s get started!

Getting Started

Packages

# Remember to install these packages using a terminal, if you haven't already!

!pip install pandas plotnine scipyWe’ll be using pandas for data manipulation, plotnine for visualization, and scipy for statistical functions.

Custom Functions

This workshop uses custom functions from the functions/ directory. You may need both:

- functions_distributions.py - for reliability and distribution functions

- functions_process_control.py - for statistical process control functions

To use these functions, you need to acquire them from the repository at github.com/timothyfraser/sigma/tree/main/functions.

Add the functions directory to your Python path

import sys

import os

# Add the functions directory to Python path

sys.path.append('functions') # or path to wherever you placed the functions folderOnce you have the functions available, you can import them:

Our Case

](https://static.wixstatic.com/media/e8dc42_9cf1b5c0e5664ebd96581ffa8891eae2~mv2_d_1960_1200_s_2.jpg/v1/fill/w_1225,h_819,al_c,q_85,usm_0.66_1.00_0.01,enc_auto/DSC00255-1-3_JPG.jpg)

Figure 12.1: Obanazawa City, Yamagata Prefecture - A Hot Springs Economy. Photo credit and more here.

For today’s workshop, we’re going to think about why quality control matters in a local economy, by examining the case of the Japanese Hot Springs bath economy! Hot springs, or onsen, are a major source of tourism and recreation for families in Japan, bringing residents from across the country every year to often rural communities where the right geological conditions have brought on naturally occurring hot springs. Restaurants, taxi and bus companies, and many service sector firms rely on their local onsen to bring in a steady stream (pun intended) of tourists to the local economy. So, it’s often in the best interest of onsen operators to keep an eye on the temperature, minerals, or other aspects of their hot springs baths to ensure quality control, to keep up their firm (and town’s!) reputation for quality rest and relaxation!

Onsen-goers often seek out specific types of hot springs, so it’s important for an onsen to actually provide what it advertises! Serbulea and Payyappallimana (2012) describe some of these benchmarks.

Temperature: Onsen are divided into “Extra Hot Springs” (

>42°C), “Hot Springs” (41~34°C), and “Warm Springs” (33~25°C).pH: Onsen are classified into “Acidic” (

pH < 3), “Mildly Acidic” (pH 3~6), “Neutral” (pH 6~7.5), “Mildly alkaline” (pH 7.5~8.5), and “Alkaline” (pH > 8.5).Sulfur: Sulfur onsen typically have about 2mg of sulfur per 1kg of hot spring water; sulfur levels must exceed 1 mg to count as a Sulfur onsen. (It smells like rotten eggs!)

These are decent examples of quality control metrics that onsen operators might want to keep tabs on!

](images/9_monkeys.png)

Figure 4.1: Monkeys are even fans of onsen! Read more here!

Our Data

You’ve been hired to evaluate quality control at a local onsen in sunny Kagoshima prefecture! Every month, for 15 months, you systematically took 20 random samples of hot spring water and recorded its temperature, pH, and sulfur levels. How might you determine if this onsen is at risk of slipping out of one sector of the market (eg. Extra Hot!) and into another (just normal Hot Springs?).

Let’s read in our data from workshops/onsen.csv!

# Add functions directory to path if not already there

import sys

if 'functions' not in sys.path:

sys.path.append('functions')

from functions_distributions import density, tidy_density, approxfun

water = pd.read_csv('workshops/onsen.csv')

water.head(3)## id time temp ph sulfur

## 0 1 1 43.2 5.1 0.0

## 1 2 1 45.3 4.8 0.4

## 2 3 1 45.5 6.2 0.916.1 Process Descriptive Statistics

First, let’s get a sense of our process by calculating some basic descriptive statistics. We’ll create a simple function to calculate the mean and standard deviation, which are fundamental to evaluating process variation.

from pandas import Series

def describe(x: Series):

x = Series(x)

out = pd.DataFrame({

'mean': [x.mean()],

'sd': [x.std()],

})

out['caption'] = ("Process Mean: " + out['mean'].round(2).astype(str) +

" | SD: " + out['sd'].round(2).astype(str))

return out

tab = describe(water['temp'])

tab## mean sd caption

## 0 44.85 1.989501 Process Mean: 44.85 | SD: 1.99Now let’s apply this to our temperature data to see the overall process mean and variation.

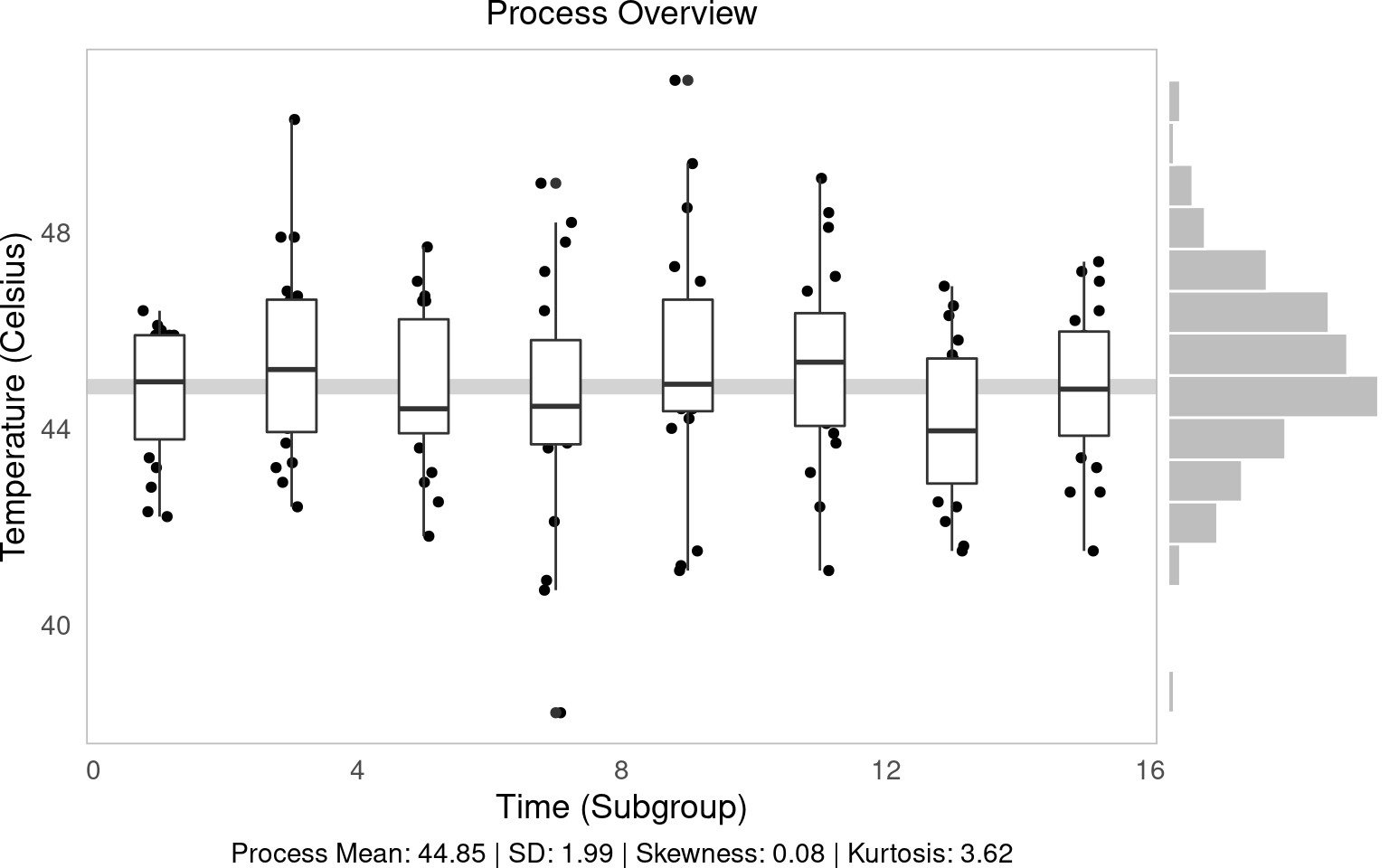

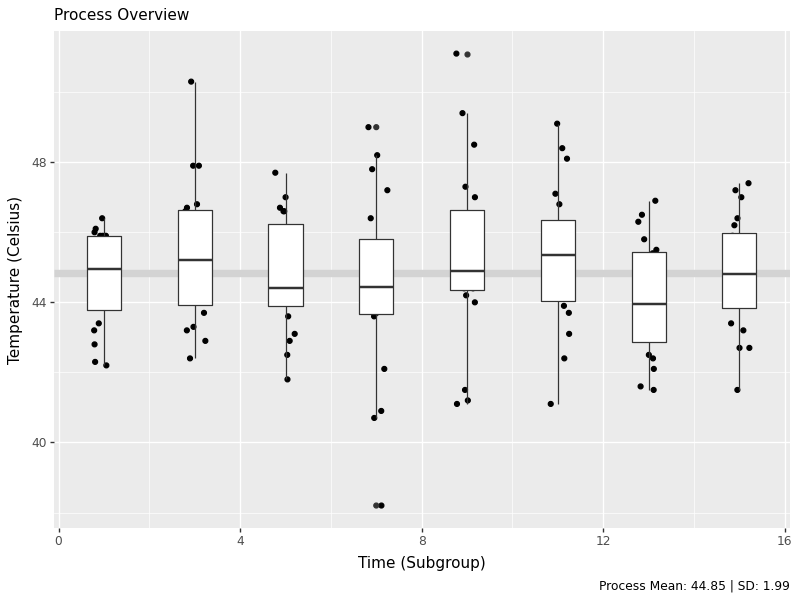

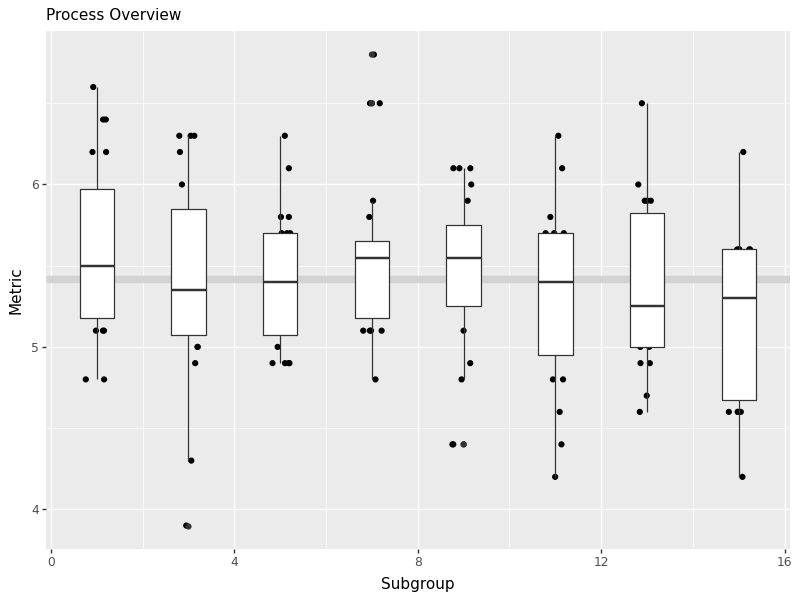

16.2 Process Overview Visual

The process overview chart is one of the most important tools in SPC. It shows us how our process behaves over time, helping us identify patterns, trends, and potential issues. We’ll create a visualization that shows individual measurements, subgroup means, and the overall process average.

g1 = (ggplot(water, aes(x='time', y='temp', group='time')) +

geom_hline(aes(yintercept=water['temp'].mean()), color='lightgrey', size=3) +

geom_jitter(height=0, width=0.25) +

geom_boxplot() +

labs(x='Time (Subgroup)', y='Temperature (Celsius)', subtitle='Process Overview', caption=tab['caption'][0]))

# Save the plot

g1.save('images/05_process_overview.png', width=8, height=6, dpi=100)

g2 = (ggplot(water, aes(x='temp')) + geom_histogram(bins=15, color='white', fill='grey') + theme_void() + coord_flip())

# Save the plot

g2.save('images/05_process_histogram.png', width=8, height=6, dpi=100)

The histogram shows us the distribution of all temperature measurements, giving us insight into the overall process variation. This helps us understand if our process is centered and how much variation we’re seeing.

16.3 Subgroup (Within-Group) Statistics

In SPC, we often work with subgroups - small samples taken at regular intervals. This allows us to distinguish between common cause variation (inherent to the process) and special cause variation (due to specific events). Let’s calculate statistics for each subgroup to see how the process behaves over time.

stat_s = (water.groupby('time').apply(lambda d: pd.Series({

'xbar': d['temp'].mean(),

'r': d['temp'].max() - d['temp'].min(),

'sd': d['temp'].std(),

'nw': len(d)

})).reset_index())

stat_s['df'] = stat_s['nw'] - 1

stat_s['sigma_s'] = ( (stat_s['df'] * (stat_s['sd']**2)).sum() / stat_s['df'].sum() )**0.5

stat_s['se'] = stat_s['sigma_s'] / (stat_s['nw']**0.5)

stat_s['upper'] = stat_s['xbar'].mean() + 3*stat_s['se']

stat_s['lower'] = stat_s['xbar'].mean() - 3*stat_s['se']

stat_s.head(3)## time xbar r sd nw df sigma_s se upper lower

## 0 1 44.635 4.2 1.342533 20.0 19.0 1.986174 0.444122 46.182366 43.517634

## 1 3 45.305 7.9 2.001440 20.0 19.0 1.986174 0.444122 46.182366 43.517634

## 2 5 44.765 5.9 1.628133 20.0 19.0 1.986174 0.444122 46.182366 43.517634Here we’ve calculated key statistics for each subgroup:

- xbar: The mean of each subgroup

- r: The range (max - min) within each subgroup

- sd: The standard deviation within each subgroup

- sigma_s: The pooled within-subgroup standard deviation

- se: The standard error for each subgroup mean

16.3.1 Total Statistics (Between Groups)

Now let’s calculate the overall process statistics that summarize the behavior across all subgroups:

stat_t = pd.DataFrame({

'xbbar': [stat_s['xbar'].mean()],

'rbar': [stat_s['r'].mean()],

'sdbar': [stat_s['sd'].mean()],

'sigma_s': [(stat_s['sd']**2).mean()**0.5],

'sigma_t': [water['temp'].std()]

})

stat_t## xbbar rbar sdbar sigma_s sigma_t

## 0 44.85 7.2625 1.93619 1.986174 1.989501These statistics give us:

- xbbar: The grand mean (average of all subgroup means)

- rbar: The average range across subgroups

- sdbar: The average standard deviation across subgroups

- sigma_s: The pooled within-subgroup standard deviation

- sigma_t: The total process standard deviation

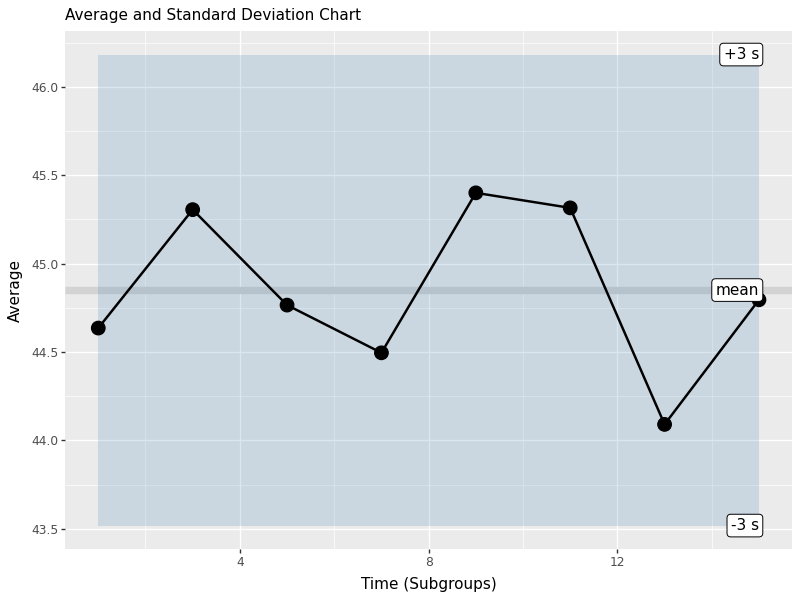

16.3.2 Average and Standard Deviation Charts

Control charts are the heart of SPC. They help us monitor process stability over time and detect when the process is out of control. We’ll create charts for both the subgroup means (X-bar chart) and standard deviations (S chart).

labels = pd.DataFrame({

'time': [stat_s['time'].max()]*3,

'type': ['xbbar','upper','lower'],

'name': ['mean','+3 s','-3 s'],

'value': [stat_s['xbar'].mean(), stat_s['upper'].iloc[0], stat_s['lower'].iloc[0]]

})

control_chart = (ggplot(stat_s, aes(x='time', y='xbar')) +

geom_hline(aes(yintercept=stat_s['xbar'].mean()), color='lightgrey', size=3) +

geom_ribbon(aes(ymin='lower', ymax='upper'), fill='steelblue', alpha=0.2) +

geom_line(size=1) + geom_point(size=5) +

geom_label(data=labels, mapping=aes(x='time', y='value', label='name'), ha='right') +

labs(x='Time (Subgroups)', y='Average', subtitle='Average and Standard Deviation Chart'))

# Save the plot

control_chart.save('images/05_control_chart.png', width=8, height=6, dpi=100)

This control chart shows:

- Center line: The grand mean (xbbar)

- Control limits: Upper and lower 3-sigma limits based on the standard error

- Individual points: Each subgroup mean plotted over time

- Shaded area: The control limits region

Points outside the control limits or showing non-random patterns indicate the process may be out of control and requires investigation.

Learning Check 1

Question

Produce the same process overview chart for pH.

[View Answer!]

def ggprocess(x, y, xlab='Subgroup', ylab='Metric'):

import pandas as pd

from plotnine import ggplot, aes, geom_hline, geom_jitter, geom_boxplot, labs

d = pd.DataFrame({'x': x, 'y': y})

g = (ggplot(d, aes(x='x', y='y', group='x')) +

geom_hline(aes(yintercept=d['y'].mean()), color='lightgrey', size=3) +

geom_jitter(height=0, width=0.25) +

geom_boxplot() +

labs(x=xlab, y=ylab, subtitle='Process Overview'))

return g

ph_chart = ggprocess(water['time'], water['ph'])

# Save the plot

ph_chart.save('images/05_ph_chart.png', width=8, height=6, dpi=100)

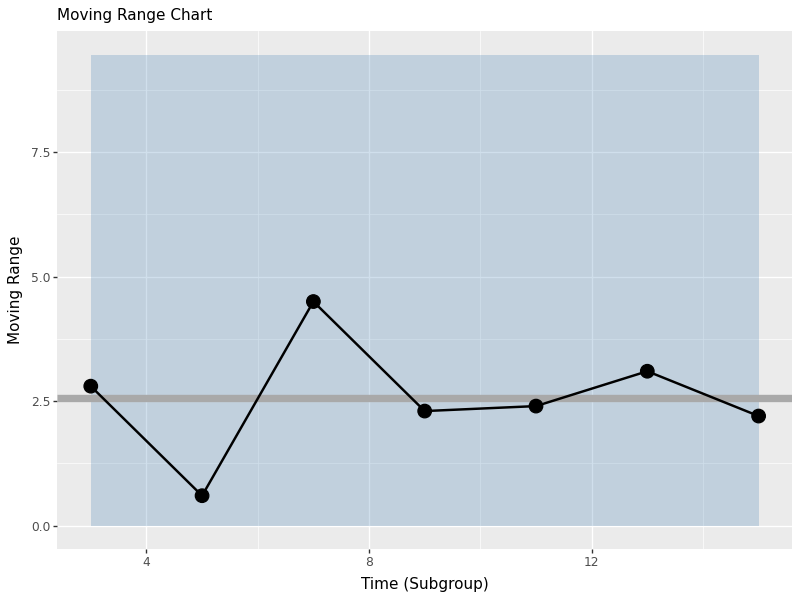

16.4 Moving Range Charts (n=1)

When we have individual measurements rather than subgroups, we use moving range charts. The moving range is the absolute difference between consecutive measurements, which helps us estimate process variation when we can’t calculate within-subgroup statistics.

indiv = water.iloc[[0,20,40,60,80,100,120,140]]

mr = (indiv['temp'].diff().abs().dropna())

mrbar = mr.mean()

import numpy as np

d2 = np.mean(np.abs(np.diff(np.random.normal(0,1,10000))))

sigma_s = mrbar / d2

se = sigma_s / (1**0.5)

upper = mrbar + 3*se

lower = 0istat = pd.DataFrame({'time': indiv['time'].iloc[1:], 'mr': mr, 'mrbar': mrbar, 'upper': upper, 'lower': lower})

mr_chart = (ggplot(istat, aes(x='time', y='mr')) +

geom_ribbon(aes(ymin='lower', ymax='upper'), fill='steelblue', alpha=0.25) +

geom_hline(aes(yintercept=mr.mean()), size=3, color='darkgrey') +

geom_line(size=1) + geom_point(size=5) +

labs(x='Time (Subgroup)', y='Moving Range', subtitle='Moving Range Chart'))

# Save the plot

mr_chart.save('images/05_moving_range_chart.png', width=8, height=6, dpi=100)

The moving range chart shows:

- Center line: The average moving range (mrbar)

- Upper control limit: Based on the estimated process standard deviation

- Lower control limit: Set to 0 (moving ranges can’t be negative)

- Individual points: Each moving range value

This chart helps us monitor process variation when we have individual measurements rather than subgroups.